40 rub test for labels

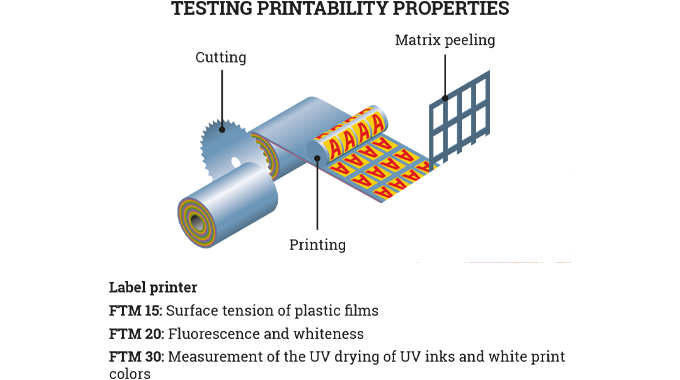

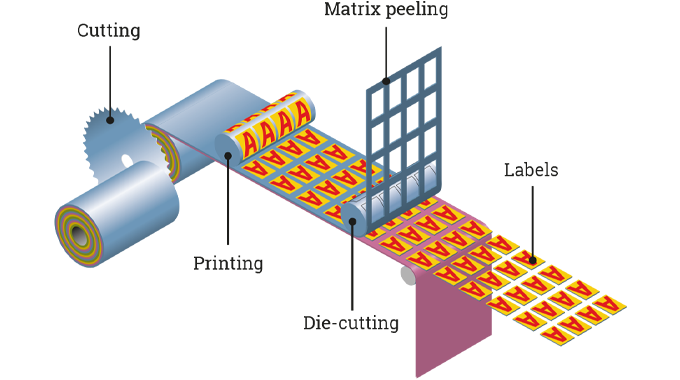

Test methods for pressure-sensitive labels | Labels & Labeling At the label converter FINAT test methods encompass printing on the label and die-cutting and matrix removal (Figure 8.3). For the label converter key requirements are to test adhesion of the final label and de-lamination properties. ... There are specific rub and scratch resistance tests for UV inks (Figure 8.9). Figure 8.9 Ink adhesion testing. Standard Test Method for Rub Abrasion Mar Resistance of High Gloss Coatings Note 1: Dry abrasion mar resistance can also be evaluated by using Test Methods D6037.If a very highly mar resistant coating is being evaluated, Test Methods D6037 will generally provide the better performance discrimination than the dry rub test described here. However, if the equipment described in Test Methods D6037 is not available, the dry rub test described in this test method affords a ...

› newsletters › entertainmentCould Call of Duty doom the Activision Blizzard deal? - Protocol Oct 14, 2022 · Hello, and welcome to Protocol Entertainment, your guide to the business of the gaming and media industries. This Friday, we’re taking a look at Microsoft and Sony’s increasingly bitter feud over Call of Duty and whether U.K. regulators are leaning toward torpedoing the Activision Blizzard deal.

Rub test for labels

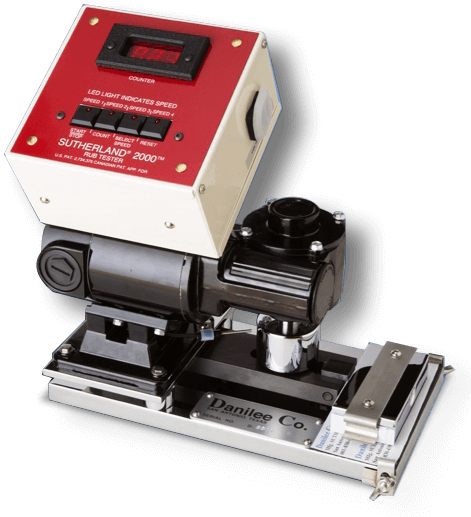

Scuff tester: best way to test rub resistance of packaging labels The Testronix scuff tester is utilized to test the abrasion resistance of the surface coating layer of printed material in order to analyze the life of the label by simulating the actual application environment. A scuff-resistance test can be used to mimic the abrasion resistance of printed, painted, or polished services. Sutherland Rub Test | ASTM D5264 | ASTM Abrasion Test | DDL The Sutherland Rub Test is performed by attaching a label to the device while a similar sample label is attached to a weight. The two samples are then rubbed against one another at a controlled speed for a predetermined number of cycles. Once the rubbing stops, the samples are visually inspected to see if the ink has worn off or not. The Sutherland Rub Test - CS Analytical The Sutherland Rub Test is performed by attaching a label to the device while a similar sample label is attached to a weight. The two samples are then rubbed against one another at a controlled speed for a predetermined number of cycles. Once the rubbing stops, the samples are visually inspected to see if the ink has worn off or not.

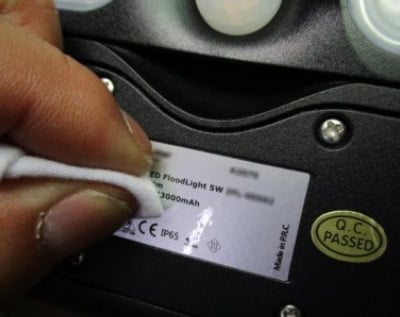

Rub test for labels. Why Is Rub Testing Important? | What is Rub Testing? For printed labels, the rub test gauges the amount of abrasion or scuff that may result during shipping, handling or storage. The test may be used for the labels of pharmaceutical products and medical devices, as well as the characters on keypads, for example. These labels must be legible and stand up to wear over time. What is the Sutherland Rub Test Procedure? | Danilee Co. To test labels, a rub test machine such as the SUTHERLAND® 2000™ Rub Tester places one label into the machine while a second label is attached to a weight. The labels are then rubbed together at an optimized speed for a predetermined time period, and afterward the shipper or tester can check the labels to assess the abrasion resistance. Self-adhesive label rubbing resistance test - Xinxing Label In order to detect the abrasion resistance of the printed label, it is necessary to perform a rub resistance test on the label.Fix the label on the anti-friction testing machine, apply a certain amount of gravity, and use the rubber to rub the label at a fixed speed.After passing the abrasion resistance test, it is proved that the material and craftsmanship of this label can meet the ... Abrasion, Rub and Scuff Resistance - Smithers The Sutherland Rub Test is performed by attaching a label to the device while a similar sample label is attached to a weight. The two samples are then rubbed against one another at a controlled speed for a predetermined number of cycles. In contrast to the rotary Smithers Rub Tester, the Sutherland Rub Tester employs a reciprocating arc motion.

cbdfx.com › collections › cbd-gummiesCBD Gummies | CBD Infused Gummies | 100% Vegan - CBDfx.com CBD is a great natural wellness supplement, due to the way it interacts with the body’s endocannabinoid system, which helps the body maintain homeostasis (balance) in several of its key functions, including mood, memory, sleep, appetite, pain and inflammation, motor control, and more. Ink Rub Tester (Sutherland Type / Linear Rub) - PackTest Also known as the Sutherland Rub Tester, this is an equipment to test printed substrates such as plastic films / foils / labels / papers or paper boards for resistance to scuffing / rubbing / smudging when 2 samples are rubbed against each other in a linear motion, under a defined pressure, at a defined speed for a defined number of rubs. › story › moneyUnbanked American households hit record low numbers in 2021 Oct 25, 2022 · The number of American households that were unbanked last year dropped to its lowest level since 2009, a dip due in part to people opening accounts to receive financial assistance during the ... Ensure Durability Of Labels To Mark Quality Of Products - prestogroup An ink rub test is performed on all labels and printed materials to ensure durability to stand the test of time. A durable label is viewed as a mark of quality. Ink Abrasion resistance tester is used to check the rubbing resistance of the printed surface of the paper, film, corrugated board etc. The advantage to conduct this test is it ensures ...

Product Quality Control. What is Rub Testing for Print? The SUTHERLAND® 2000™ Rub Tester is a standard in the industry when it comes to rub testing for print and fabrics for over 60 years. It works by utilizing motor-driven abrasion testing. The label is put in the machine and a similar label to a weight is also attached. Label rub and scuff testing | Resource Label Group - Advanced Labels NW Your label printer will need a few printed and varnished production labels. The rub and scuff test involves a standard two-pound or four-pound weighted block, with your packaging insert affixed to its base. This weighted insert is then dragged back and forth in an arc across the face of your label at its weakest point. Rub Testing Procedures Explained | Rub Tester | Danilee Co. Mount the strips in the same manner as for a dry rub, using the two-pound test block. Preset the tester for one rub. Place three to six drops of water on the printed surface so that the test block will cover them. Place the block in position and immediately press the "start" button. After one stroke, examine both surfaces for color transfer. Ink Rub Tester | Qualitest - WorldofTest.com Best Application: Ink Rub tester on plastic Rub resistance describes the ability of printed material to withstand marking, scuffing or smudge during handling in conversion, packaging, transportation, distribution and use. QT-IRT simulates a similar environment to test the rub resistance on printed materials. Applications Features/Advantages

Label Durability Testing - Eurofins Medical Device Testing Choose Eurofins Medical Device Testing to help you: Assess the robustness of your labels to verify that your barcodes will remain readable after being subjected to the stresses of shipment. Ensure your products meet the latest UDI regulations. Testing Available: Tape Testing - ASTM F2252. Sutherland Rub Testing - ASTM D6264.

Rub test Archives - Resource Label Group Our suite of easy-to-use, essential applications simplify processes and save valuable time.

Solvent Resistance Rub Test - ASTM D4752 - TRL This test method is used to determine the degree of cure of a baked film by the paint film resistance to a specified solvent. The Solvent Rub Test is usually performed using methyl ethyl ketone (MEK) as the solvent. The MEK resistance or degree of cure applies to paint topcoats and primers. ASTM D4752 involves rubbing the surface of a baked ...

Sutherland Rub Test - Packaging Compliance Labs Packaging Compliance Labs provides ASTM D5264 standard Sutherland Rub testing to gauge the amount of scuffing or abrasion caused during shipping, handling, and storage. For medical packaging this test is critical to ensure that labeling remains legible over the course of time. Industry Application

› newsNews | The Scotsman Scottish perspective on news, sport, business, lifestyle, food and drink and more, from Scotland's national newspaper, The Scotsman.

› news-events › public-health-focusFDA Regulation of Cannabis and Cannabis-Derived Products ... [1] Gray, et al. Identifying Prenatal Cannabis Exposure and Effects of Concurrent Tobacco Exposure on Neonatal Growth. Clinical Chemistry. 2010; 56(9): 1442-1450. [2] Gunn, et al. Prenatal ...

› 2022/10/19 › 23411972Microsoft is building an Xbox mobile gaming store to take on ... Oct 19, 2022 · Microsoft’s Activision Blizzard deal is key to the company’s mobile gaming efforts. Microsoft is quietly building a mobile Xbox store that will rely on Activision and King games.

Benefits of Ink Rub Testing | Sutherland 2000 | Danilee Co. An ink rub test is a test of a label whereby a label is rubbed against an abrasive. It might be rubbed several hundred times and afterwards the label is inspected for readability of the information on the label. Different fluids can also be employed like such as alcohol and even soaps.

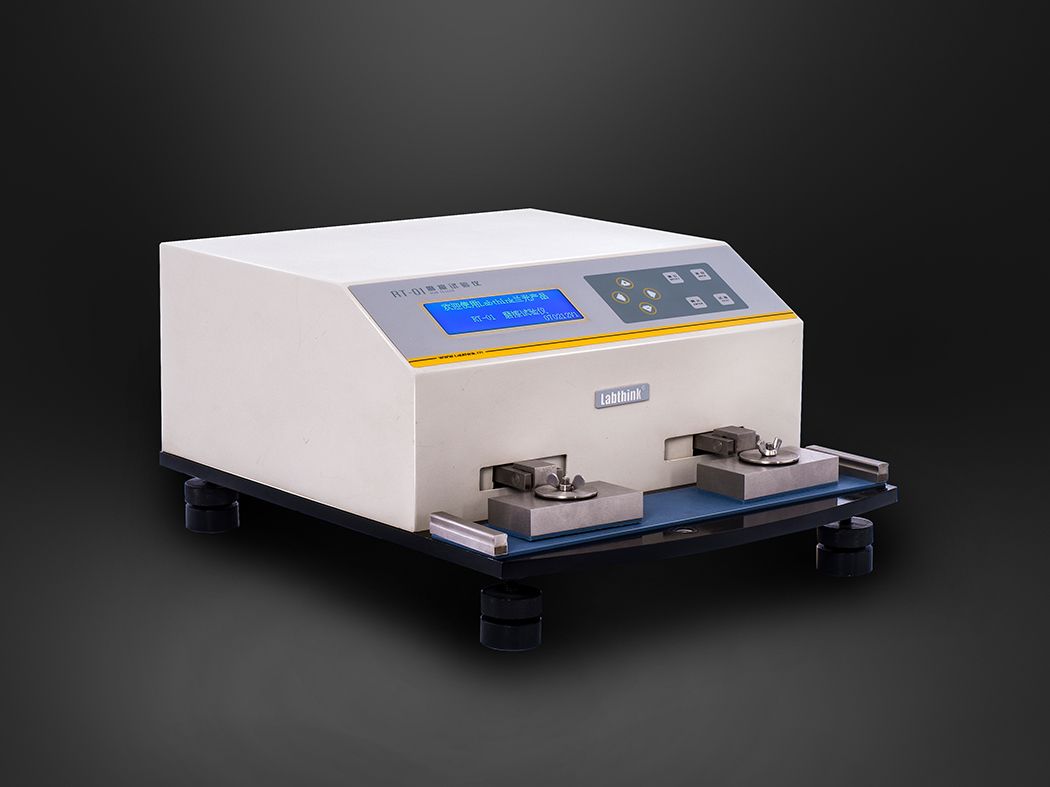

Ink Rub Tester - Rub Tester for Printing Inks And Coatings Manufacturer ... Ink Rub Tester is applicable in ink rub test of ink layer of materials like labels, folding cartons, corrugated boxes etc. Ink Rub Tester can help users to analyze the reasons of lower abrasion assistance, ink layer falling-off, lower printable of PS boards and adhesion of coating layers of other products. Ink Rub Tester conforms to standards of ASTM D5264, TAPPI T830, JIS K5701 and GB 7706.

Pharmaceutical Label Testing and Print Qualification - Westpak A Sutherland Rub Test evaluates the scuff or rub resistance of printed or coated surfaces, paper, paperboard, films, and printed materials. In a Chemical Resistance Test, labels can be manually cleaned with IPA and peroxide wipes to determine if the label smudges, smears, or degrades in legibility. Peel Adhesion tests can be used to measure a ...

How To Do A Label Marking Durability Test [Video and Infographic ... How to Do an Isopropyl Alcohol Rub Test What you'll need: Isopropyl Alcohol Toothbrush Timer Immerse your label in isopropyl alcohol for 3 minutes. Remove the label from the alcohol. Then, use a toothbrush to scrub the impression 10 times. Repeat steps a-b twice more for a total of 3 cycles. Review the label impression for degradation.

Scratch or Rub Resistance of Labels on Packages - prestogroup ASTM F2497-05 - Standard Practice for Abrasion and Scuff Resistance of Inkjet Media by the Sutherland Rub Tester BS 3110:1959 - Methods for measuring the rub resistance of the print To know more information about its features, price, and technical specifications, give us a call at +91 9210903903 or email us at info@prestogroup.com.

How to Do an Isopropyl Alcohol Rub Test - YouTube UL Compliant Solutions: do you determine the durability of your thermal tran...

Sutherland Rub Test - Basic Concept reveals for the evaluation of test Preparation of Sutherland Rub Tester. A room must be between (22 and 24 degrees Celsius or 71.4 and 75.4 degrees Fahrenheit). A room must be between 48 and 52% humidity. Decide how many strokes to set the Rub Tester at and record. The testing instrument in IPL is set to 40 rubs, which will use in this research. Test.

› Sharpie-Rub-Laundry-Marker-SNSharpie Rub-A-Dub Laundry Marker, Pack of 3 (SN31101PP-2) Jul 02, 2014 · I tested this marker out on some woven name labels (Wal front - Woven Name Labels Sew in School Name Tags). This marker bleeds less than a regular fine Sharpie but more than an ultra fine (skinny) Sharpie. All three markers survived the washer and dryer just fine.

Rub test with ultra-solvent resistant polyester label and Skydrol® Video demonstrating the effect of 50 double rubs using a Skydrol® soaked cloth on a CILS-TMWUSPET (LSE) ultra-solvent resistant polyester label that was thermal transfer printed using a...

Learn Printing Adhesion Testing Like a Pro - InTouch Firmly press a strip of tape on the test surface. Generally, test surfaces can be a printed product logo, or any other surface on a product that contains printed material. Rub the tape repeatedly until all air trapped underneath is removed. With one rapid motion, pull the tape perpendicularly away from the test surface to remove it completely.

PDF Compliance Guidelines for Marking and Labeling Systems - UL Compliance Guidelines for Marking and Labeling Systems - UL

The Sutherland Rub Test - CS Analytical The Sutherland Rub Test is performed by attaching a label to the device while a similar sample label is attached to a weight. The two samples are then rubbed against one another at a controlled speed for a predetermined number of cycles. Once the rubbing stops, the samples are visually inspected to see if the ink has worn off or not.

Sutherland Rub Test | ASTM D5264 | ASTM Abrasion Test | DDL The Sutherland Rub Test is performed by attaching a label to the device while a similar sample label is attached to a weight. The two samples are then rubbed against one another at a controlled speed for a predetermined number of cycles. Once the rubbing stops, the samples are visually inspected to see if the ink has worn off or not.

Scuff tester: best way to test rub resistance of packaging labels The Testronix scuff tester is utilized to test the abrasion resistance of the surface coating layer of printed material in order to analyze the life of the label by simulating the actual application environment. A scuff-resistance test can be used to mimic the abrasion resistance of printed, painted, or polished services.

Post a Comment for "40 rub test for labels"